CNC machines have greatly revolutionized the manufacturing industry. They’ve made it easier to process goods, enabling manufacturing companies to increase their production significantly. Most companies like Inventables sell these machines to businesses and other companies who’d like to improve their production.

However, before purchasing a CNC machine for your company, you need to know what it is and how it operates. This article gives you some information that you need to know about these machines.

Understanding A CNC Machine

CNC machines are controlled by computers. CNC stands for Computer Numerical Control. It’s derived from the older term “Numerical Control.” Older NC machines didn’t require computers to operate.

However, CNC machines act like robots and have programs that instruct them to move their cutters and spindles. The programs also dictate the direction that the cutters move in and tell the machine which cutter to use.

The inventions of CNC machines have led to enhanced productivity because they run automatically without operators’ constant supervision. Before this automation, companies used hydraulic tracer systems to cut tools.

Types Of CNC Machines

There are various types of CNC machines, including lathes, mills, water jets, lasers, routers, 3D printers, and electronic discharge machines.

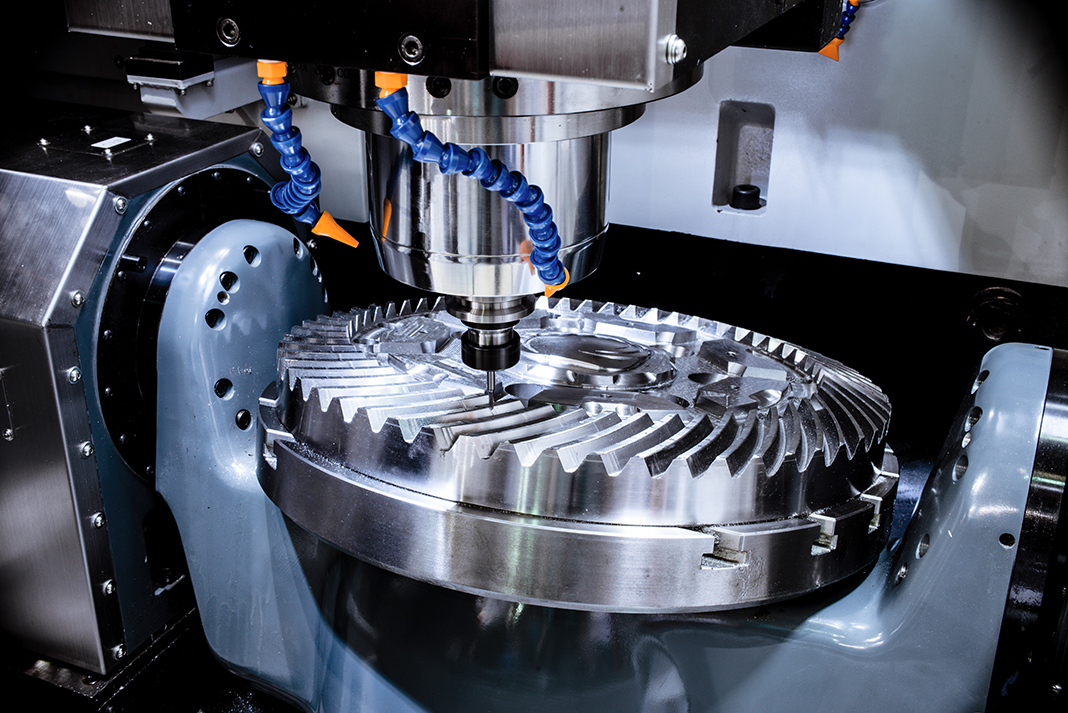

Milling Machines

A mill is required for cutting chips. A CNC mill uses a cutter that’s inserted in the spindle. Once in the spindle, it rotates and slices off chips, a process known as milling. These machines can cut chips in 3D, though some older versions only cut in two dimensions.

These dimensions are referred to as axes and are labeled as X,Y, and Z. Every axis is managed by a stepper motor or servo, which is controlled by a program. There are two types of CNC milling machines, namely the horizontal and the vertical machines.They derive their names from how they’re parallel to the spindle.

CNC Lathes

Lathes are regarded as universal CNC machines because they can develop parts for creating another lathe. When inserted in a spindle, lathes spin workpieces and use fixed cutting tools to slice chips from a workpiece. Their geometry makes them ideal for symmetrical chips.

These machines use a G-code and two axes – X and Z, to drive a cutting tool. You can use them for various functions and explore their variations. The process of cutting workpieces using a lathe is referred to as turning. That’s why heavier CNC lathes are known as turning centers.

Turning centers are fully enclosed and have tool changers called turret that they use to perform operations. A more sophisticated turning center can function as a milling machine. However, it can only be very effective if a bar feeder or a bar puller is added. You can load raw materials on the machine, and it’ll automatically give you finished products.

CNC Routers

A router resembles a CNC mill, though it uses a different configuration called a gantry. You can use them to cut wood and other parts that need precision. However, they’re not as effective and precise as CNC mills because of their gantry design.

Final Thought

CNC machines can help you increase production, especially if you have a company that requires accurate cutting. Knowing what CNC machines are and their types can help you select the right one that’s suitable for your production needs.